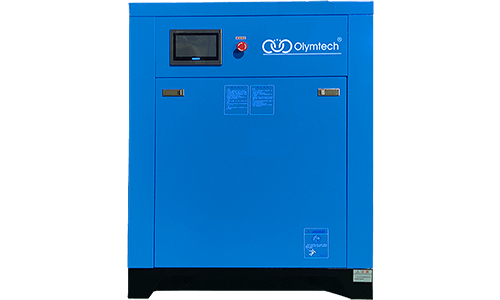

| CY series Olymtech VSD permanent magnet oil cooled motor screw air compressor | ||||||||||

| Model | Max Working Pressure | Capacity | Motor Power | Transmission | Connection | Net Weight | Dimension (Lx W x H) | |||

| -- | bar | psig | m3/min | CFM | hp | kw | inch | kgs | mm | |

| C15Y | 7 | 102 | 2.5 | 88 | 20 | 15 | Direct Drive | G1" | 300 | 1050*600*1125 |

| 8 | 116 | 2.3 | 81 | |||||||

| C22Y | 7 | 102 | 3.8 | 134 | 30 | 22 | Direct Drive | G1" | 360 | 1050*600*1125 |

| 8 | 116 | 3.3 | 116 | |||||||

| C37Y | 7 | 102 | 6.7 | 236 | 50 | 37 | Direct Drive | G1-1/4" | 390 | 1200*650*1500 |

| 8 | 116 | 6.4 | 226 | |||||||

| C55Y | 7 | 102 | 10.2 | 360 | 75 | 55 | Direct Drive | G2" | 1000 | 1550*1160*1600 |

| 8 | 116 | 9.4 | 331 | |||||||

| C75Y | 7 | 102 | 13.2 | 466 | 100 | 75 | Direct Drive | G2" | 1050 | 1550*1160*1600 |

| 8 | 116 | 12.2 | 430 | |||||||

| ● According to the standard of GB19153-2009 ● Compressor stage: one stage compression ● Exhaust temperature: ambient temperature + 15℃ ● Power supply: 380v/50hz/3ph, 415v/50hz/3ph ● Please contact with us for any specification that is not within the above mentioned standard | ||||||||||

- Permanent magnet OIL COOLED motor

- Reliable inverter technology

- Side hot air exhaust design

- Efficient transmission

Permanent magnet OIL COOLED motor

1.IE5 super high efficiency oil cooled motor, temperature resisitance reach to 180℃

2.IP65 protection levelmotor, suit for use in the heavy duty factory, runs every 24 hours

3.No fan blade, wind resistance loss is 0

4.Oil is a much better heat transfer media than air cooling. Oil cooled motor working temperature is at least 10°C lower than air cooled motor

5.Lower noise becasue the motor case is wrapped by oil

2.IP65 protection levelmotor, suit for use in the heavy duty factory, runs every 24 hours

3.No fan blade, wind resistance loss is 0

4.Oil is a much better heat transfer media than air cooling. Oil cooled motor working temperature is at least 10°C lower than air cooled motor

5.Lower noise becasue the motor case is wrapped by oil

Reliable inverter technology

1.Average energy saving can reach to 35% during air demand fluctuation

2.Won't waste air when unloading

3.VSD starting can reduce the impact of the power grid

4.Inverter, PLC and controller are perfert match, can give fast respone to users

2.Won't waste air when unloading

3.VSD starting can reduce the impact of the power grid

4.Inverter, PLC and controller are perfert match, can give fast respone to users

Side hot air exhaust design

1.Particularly suited for congested low ceiling level air compressor room. Side cooling ‘BLAST’ all hot air directly out of the compressor room through opening on wall or wire mesh fencing without the use of expensive hot air ducting!

2. The cooler is placed vertically, which avoid the dust falling on the cooler from the top. Prolong the cooler service life.

2. The cooler is placed vertically, which avoid the dust falling on the cooler from the top. Prolong the cooler service life.

Efficient transmission

Motor and air-end is one shaft transmission, no belt, no gear, no coupling, energy is 100% transmission, efficient and no wastage

SPECIFICATION

Relative products in the same category